By Dr. Laura Haupert, Ecosorb

Each day, wastewater treatment agencies face the challenges of efficiently collecting, treating, and discharging refuse in compliance with laws, regulations, and ordinances. One such challenge is managing foul odors—failure to do so prompts complaints from residential and commercial neighbors, resulting in negative press and possibly regulatory consequences.

Wastewater facilities often attempt to control odors with masking techniques, but overpowering one unwanted smell with another is far from ideal. Below is a summary of my article in the November 2023 edition of Wastewater Digest, titled “Manage wastewater odors with plant-based neutralizers,” which discusses modern neutralizers that address the root of the problem by chemically altering the molecules responsible for malodors to render them impotent.

The need for plant-based alternatives

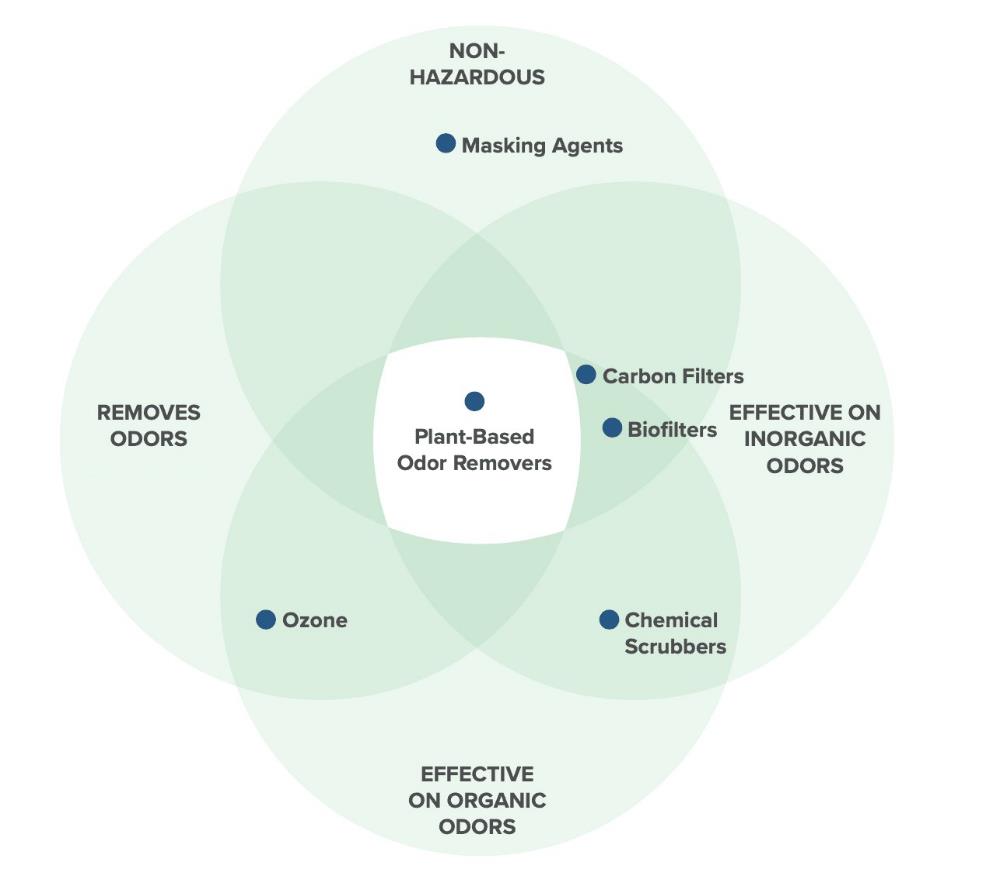

Most conventional odor control methodologies have critical shortcomings. For example, some contain hazardous materials, some are ineffective against certain types of odors, and many are expensive or unwieldy to operate.

In contrast, plant-based neutralizers are safe, require relatively little equipment, and are effective in almost every odor-removal application because they use custom formulations designed to treat specific odors.

Designing an effective plant-based solution begins with gas sample collection at the process site. These samples are taken to a lab and analyzed via gas chromatography mass spectrometry (GC-MS) to determine precise molecular composition. Scientists use this information to formulate blends of plant oils tailored to the odors of each facility.

Odor remover delivery systems

In most cases, plant-based odor neutralizers are distributed with either atomization or vaporization systems. In atomization systems, concentrated formulations are diluted with water and sprayed into the air.

Unlike atomization systems, vaporization systems pump pre-mixed formulations that do not require water dilution through perforated pipes as dry vapor.

Compared to atomization systems, they distribute smaller droplets, resulting in higher odor absorption, and they do not use nozzles, reducing maintenance requirements as nozzles can plug.

Cloud-based interfaces, such as Ecosorb’s Ecolink, provide remote access to odor control systems from any device with a web browser, empowering operators to:

- Remotely start, stop, and change system operating mode;

- Identify low product levels;

- Track and trend flow rates, energy use, downtime, and other key performance indicators.

- Send alerts and notifications;

- Adjust product dosage to coincide with fluctuating odor-producing periods;

- Encrypt data for transit and storage; and

- View metrics, charts, and diagrams on an intuitive dashboard.

Plant-based neutralizers in practice

An award-winning wastewater treatment plant in the Southeast U.S. faced odor challenges as residential communities emerged in the vicinity. The new neighbors complained about the unpleasant odors produced by the activated sludge process as well as biosolid digestion and belt filter press operations.

After an evaluation by Ecosorb, the plant now treats impacted areas with a plant-based formulation distributed via atomization systems. According to plant management, Ecosorb is the most effective odor control solution the facility has used, and complaints have dropped drastically since installation.

Plant-based odor neutralizers are safe, affordable, eco-friendly, easy to use, and effective for treating wastewater odors. Robust odor control empowers wastewater facilities to focus on treatment and disposal while maintaining good relations with neighbors.