Remove odors from storage tanks as you clean.

Keep Smells From Escaping During Industrial Storage Tank Cleaning

Prior to cleaning, storage tanks are vented to the atmosphere to reduce internal gas content to a level below its lower explosion limit (LEL). This allows workers to access the tanks safely.

During venting, odors escape into the atmosphere creating a nuisance to nearby residents, businesses, and employees. Industrial tank cleaning also results in production downtime that lowers plant profitability.

Combat odors resulting from industrial storage tank cleaning with Ecosorb® from OMI Industries. This natural, industrial-grade odor eliminator can be used in any industry from asphalt production and wastewater treatment, to food processing and composting.

Ecosorb® products are effective on most odors associated with storage tank cleaning, including:

- Naptha

- Diesel

- Crude oil

- Amines

- Phenols

- Formaldehyde

- Ammonia

- Sulfur dioxide

Benefits of Ecosorb

Natural

Ecosorb uses the natural power of plant oils to remove odors caused by tank cleaning.

Safe

Non-toxic, non-hazardous, biodegradable, non-flammable, and no harmful VOCs.

Effective

Proven by independent and customer labs to reduce volatile emissions.

Complete

Custom formulations for odorous gases from any industry.

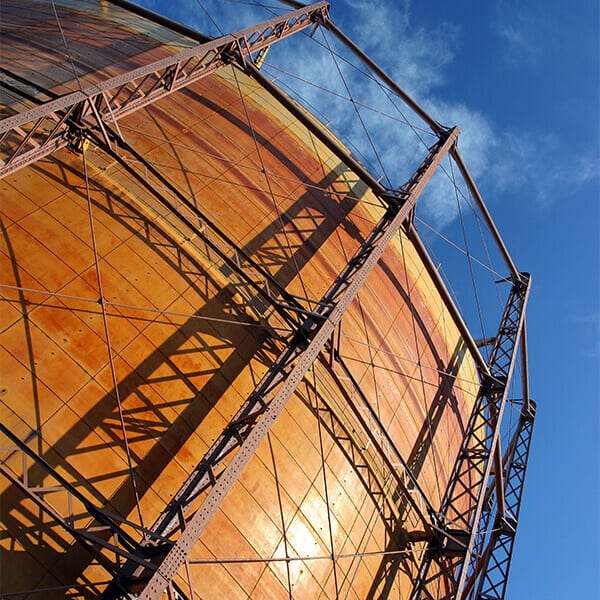

Crude Oil Storage Tanks

Prior to cleaning tanks, they must be vented to lower the explosion limits – a process that releases crude oil odors to the atmosphere. An Ecosorb system program can provide reliable industrial tank cleaning odor control even in 500,000 barrel tanks.

Refinery Storage Tanks

Spent tanks at refineries often contain traces of naphtha and diesel that can escape during industrial storage tank cleaning. In residential areas, this means costly delays waiting for favorable wind directions. Ecosorb natural odor control products allow cleaning at any time.

How to Use

There are many possible ways to use Ecosorb during tank cleaning, including the use of vaporization or atomizations systems. Tank venting with a “Coppus” fan is normally done prior to tank cleaning and Ecosorb can easily be injected into the direct-air line of the Coppus fan using a low volume chemical injection pump.

Some distributors and customers inject Ecosorb into a steam line, spray inside tanks, and reduce H2S levels. After an hour or so, emissions and odors have been eliminated to a low enough level to allow treated air to escape. A Canadian environmental company used a similar process to clear odors from ammonia storage tanks.

Products

- Ecosorb 606

- Custom blends

Packaging Options

- 5-gallon pails

- 55-gallon drums

- 275-gallon totes