Natural Solutions for Controlling Food Processing Odors

Whether too much of a good thing, or seriously unpleasant, food facilities must control odors. A scientific approach using natural neutralizers solves the problem.

By Laura Haupert, PhD

Visitors to Chicago’s downtown are often greeted by the aroma of chocolate from a nearby processing plant. Most people walking outside find it very pleasant, but others consider it annoying and have complained to the EPA. Even the aroma of chocolate can be a problem for those exposed to it continuously.

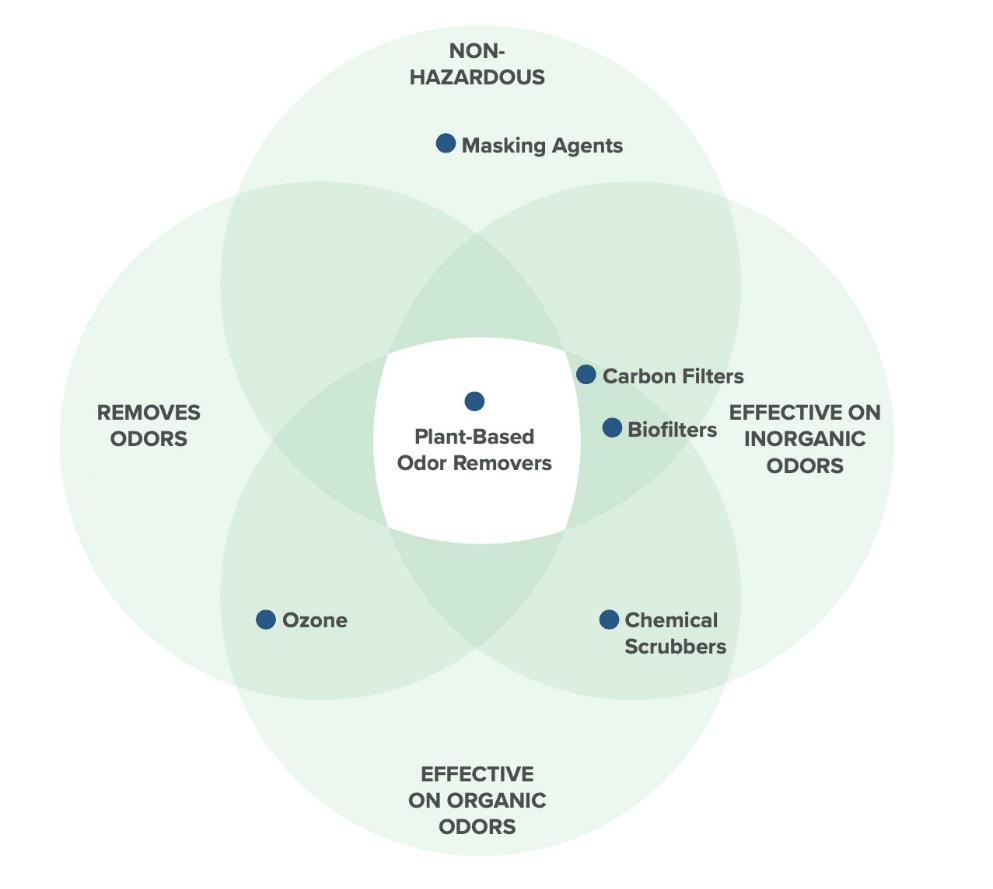

Getting rid of smells can be a challenge for many industries, including food processing, but being a good neighbor to the surrounding community often calls for serious efforts to do just that. Some try to mask the offending odors other scents, but this is rarely an effective method over time. The best approach is to break down the smelly molecules, neutralizing the unpleasant odors. How this works is the topic of my article in the April issue of Food Engineering, Plant-Based Oils Can Neutralize Odors at Food Facilities.

This concept is easy to understand, but challenging to implement because it requires thorough knowledge of the products involved. Odors are unpleasant because of the presence of specific molecules or groups of molecules. They can also originate at different points of a process. For food processors, an odor may result from simply opening an ingredient container, from processing such as cooking, or from a waste product. It may be a combination of several things, yielding a mix with some elements worse than others.

The challenge is determining the most problematic compounds and how they can be broken down even while airborne. As the article describes:

In the lab, scientists study gaseous samples collected from facilities using gas chromatography mass spectrometry (GC-MS) to determine the molecular makeup of odors, even those present in minute amounts. A GC chromatogram is a visual output of the data recorded by the detector. Each compound detected appears as a single peak on the graph. Once the odor-causing compounds are identified, the scientists concoct a formulation using plant oils to molecularly neutralize the odors when the compound is combined with the odors in the atmosphere.

So, plant oils? Yes, there are many natural plant-based chemical components that are excellent for neutralizing a wide variety of problem odors from food processors. OMI’s Ecosorb family of neutralizers uses basic science to harness the power of plants to create eco-friendly industrial odor eliminators. Our proprietary blend of oils includes those from pine, aniseed, clove, lime, and other sources to tackle the toughest smells without dangerous side effects. This makes them particularly well-suited to food processors.

In most cases, these are sprayed as close to the source as possible, where the offending odor is most heavily concentrated. The droplets neutralize the odor molecules on contact, even when airborne, and formulations can be tailored to specific processes to maximize efficiency.

The most challenging aspect of this is choosing the best odor eliminator from the range of products OMI offers. Some common odors, such as fish waste, are well understood, while others require deeper analysis to match a solution to the source. Fortunately, OMI Industries has the experience and scientific know-how to solve these challenges, whether complex or simple. You can download a handy guide for Ecosorb solutions to start the process.

LinkedIn Summary: While the aroma of baking cookies can be mouth-watering, many food processing odors can be unpleasant or overwhelming. Ecosorb odor neutralizing agents from OMI Industries can neutralize them at the source using plant-based safe ingredients.

Tweet: To control odors in and outside a facility, food processors can use Ecosorb odor neutralizing agents with safe plant-based ingredients.