Overcome Food Processing Odors with Plant-Based Neutralizers

By Glenn B. Crisler II, Ph.D., Ecosorb

From pungent fish sauce smells to lingering cheese aromas, mitigating odors is a crucial challenge for industrial food processors. Because traditional masking solutions are temporary at best, and toxic at worst, a more effective approach is necessary.

My article in the July 2024 issue of Food Engineering, titled “Natural Neutralizers are the Key Ingredient for Safe and Effective Odor Control,” discusses a safe, effective, and cost-efficient alternative: molecular neutralization with plant-based products.

Science of odor neutralization

Molecular neutralization applies the principles of molecular polarity and binding.

Polar molecules exhibit an uneven distribution of electrical charges across their constituent atoms, resulting in a slight positive charge on one end and a slight negative charge on the other.

Molecular neutralizers are designed to bind to these polar molecules in a process called adsorption, and then the neutralizers fully envelop the molecules through absorption. These reactions leave behind molecules that are undetectable to the senses, significantly reducing unpleasant odors in industrial settings.

Because odor neutralizers are designed to bind to specific molecules, different formulations are required for different industrial applications.

Proven formulations for diverse needs

As a top supplier of natural odor control products, Ecosorb leverages extensive knowledge, research, and laboratory technology to develop specialized formulations for targeted applications. While certain situations require custom formulations, standardized blends are effective in typical applications and have multiple advantages:

- Extensive supplier expertise

- Reduced lead times

- Turnkey solutions for faster startup

- Proven product performance

- Adaptable to process changes

- Optimal support

When necessary, experienced suppliers can also provide customized solutions.

Advanced sample collection and analysis

Crafting a custom formulation begins with collection of air samples from the facility using Markes thermal desorption tubes. These advanced containers are highly effective at collecting odor-causing volatile organic compounds (VOCs), and they preserve samples for up to several weeks.

Each tube contains sorbent material designed to efficiently capture airborne odor molecules during sampling. Air is drawn through the tube by a pump for up to about five minutes, highly concentrating any VOCs present in the sample, even when odorous molecules are present in trace amounts.

An Ecosorb field scientist collects samples around a wastewater treatment plant to ascertain a facility-wide odor profile.

This concentrated sampling process facilitates easier identification of each compound.

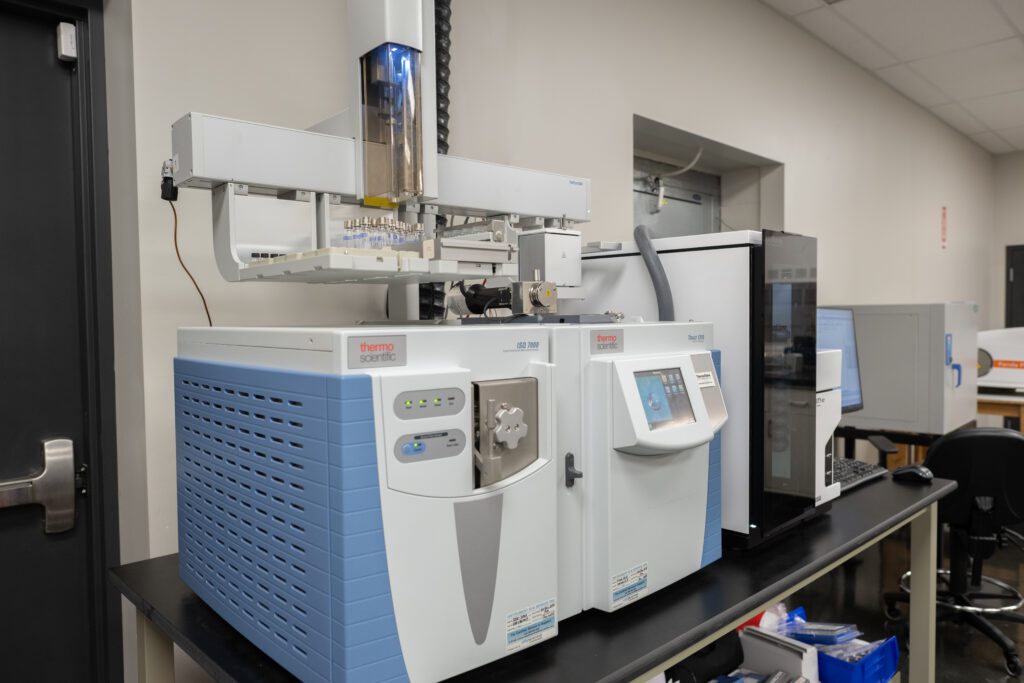

In the lab, the tubes are heated to release the sample molecules from the sorbent material. The molecules are then analyzed via gas chromatography-mass spectrometry (GC-MS) to identify each chemical compound, and with this information, our scientists formulate plant oil blends to neutralize odor-causing substances.

A GC-MS is used to identify odor-causing substances in facility air, empowering scientists to prescribe plant-based formulas to neutralize the offending odors.

This combination of advanced sampling, analytical technology, and industry expertise makes successful odor control achievable even in niche cases.

Mitigating odors at a liquid fertilizer production plant

A US-based food processor that converts scraps into liquid fertilizer faced odor complaints from industrial and commercial neighbors, so they called in Ecosorb to sample and analyze air around the facility.

A converter of food scraps to liquid fertilizer turned to Ecosorb to mitigate mounting odor complaints from neighbors.

The team prescribed Ecosorb 806 for dosing at exhaust nozzles via an atomization system. Upon deployment, complaints ceased almost immediately, enabling the facility to continue production without further issue.

Effective odor relief

In conclusion, plant-based odor neutralizers offer a safe, environmentally friendly, and cost-effective solution for industrial odor control, allowing processors to shift their focus from managing complaints to enhancing production. By collaborating with expert suppliers and utilizing tailored neutralization strategies, manufacturers can achieve effective odor management, foster a healthy working environment, and maintain positive relationships with their communities.