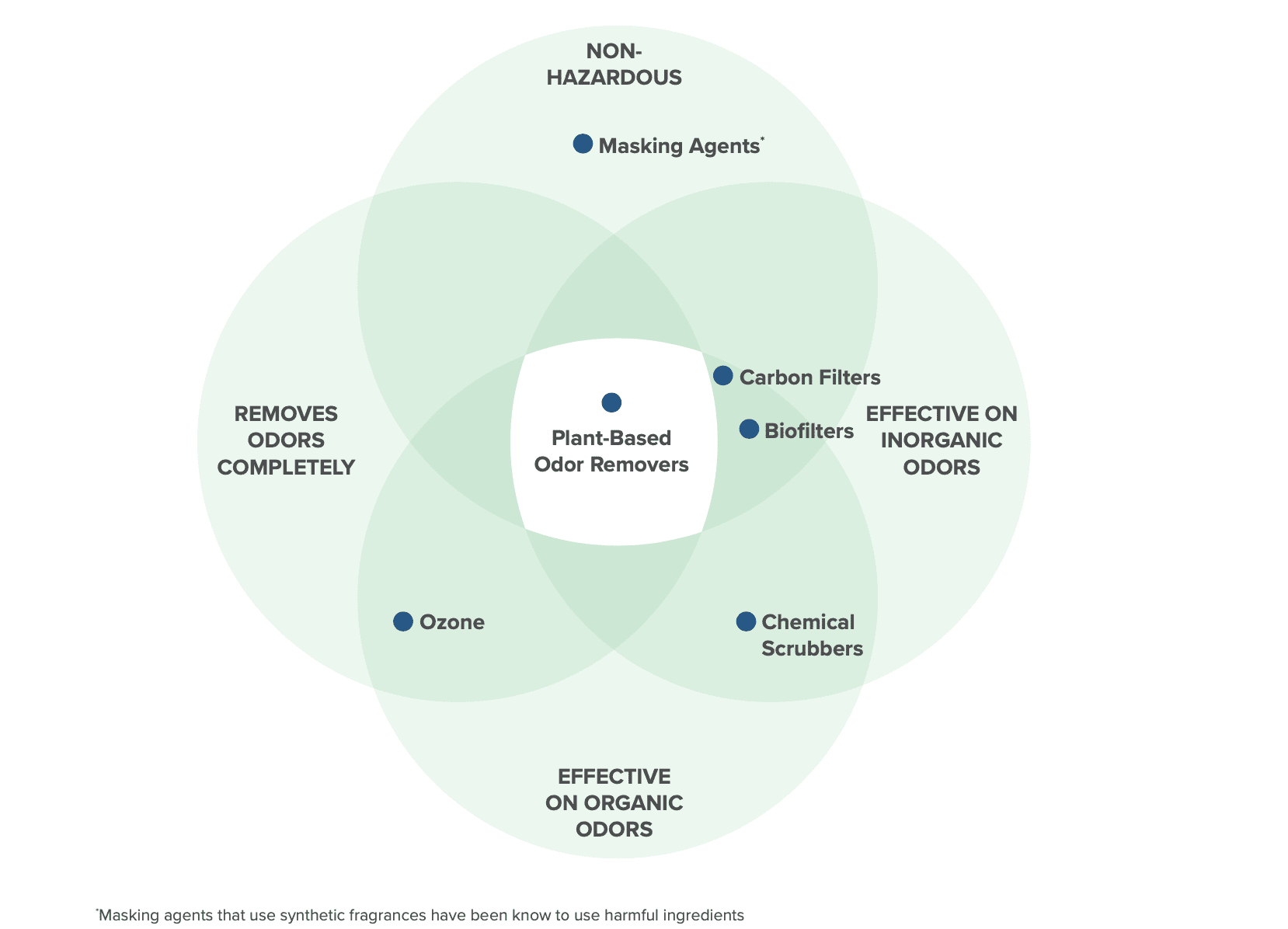

When you examine plant-based odor removers, like Ecosorb, against other common odor solution techniques, the comparisons are stark.

Most solutions require complex systems which are costly to build, use, and fix, and demand expertise to maintain.

Many solutions depend on hazardous materials that can produce harmful compounds, exhaust, or even residual odors.

It’s clear. Ecosorb plant-based odor eliminators are the only option for safer, more effective, industrial-strength odor control.

Use this easy-to-understand guide as you explore your odor control options.

Use this easy-to-understand guide as you explore your odor control options.