Eliminate Odors with Standardized Formulations

Article by Dr. Laura Haupert, Ecosorb

Process manufacturers regularly face challenges managing unwanted odors, prompting complaints from employees and neighbors. Fortunately, there is a growing catalog of modern, safe, and effective odor neutralizers available for use in industrial settings.

My article in the May/June issue of Control Engineering, titled “Safely and Sustainably Absolve Industrial Malodors with Standardized Formulations,” provides an overview of plant-based odor neutralizers and shows how standardized formulations can be used to treat pungent odors in many industries.

What causes offensive odors?

Odors originate from volatile organic compounds (VOCs), airborne chemicals with a wide variety of molecular structures. When humans inhale, VOCs enter the nasal cavity and bind with proteins on olfactory receptor neurons, triggering electrical signals that travel to the brain and create the perception of smell. By eliminating offending molecules at the source, manufacturers can prevent the spread of pungent VOCs.

Traditional odor abatement drawbacks

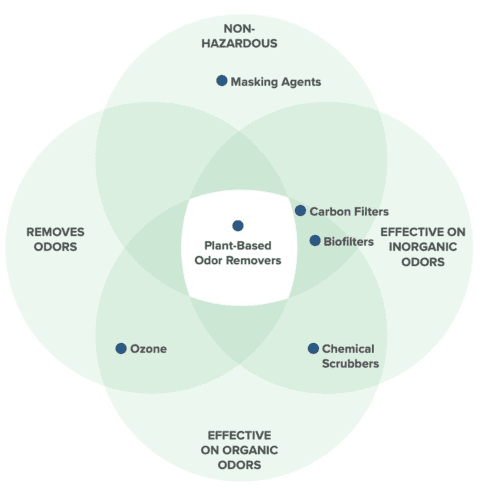

Traditional odor control methods may help reduce process-related malodors, but they often have limited effectiveness or significant drawbacks. For example, masking agents fail to address the root cause of malodors and merely cover one smell with another; thermal oxidation is effective, but it harms the environment; and chemical scrubbing is effective in some industries, but it is maintenance-intensive and costly.

Standardized odor neutralization solutions

Odor neutralization offers a more sustainable and effective approach to odor control. Leading suppliers use advanced techniques like gas chromatography-mass spectrometry (GC-MS) to identify VOCs, and they then create specialized formulations designed to neutralize the odorants on contact. Compared to traditional methods, odor neutralization has long-lasting effectiveness and is safe, versatile, and cost-efficient.

Standardized formulations are crafted for a variety of applications within each industrial sector. While specialized blends may be required in some situations, standardized solutions are advantageous in most cases. Among these benefits, they reduce lead and startup time, provide flexibility for process modifications, ensure supplier support, and are proven effective through extensive disbursement.

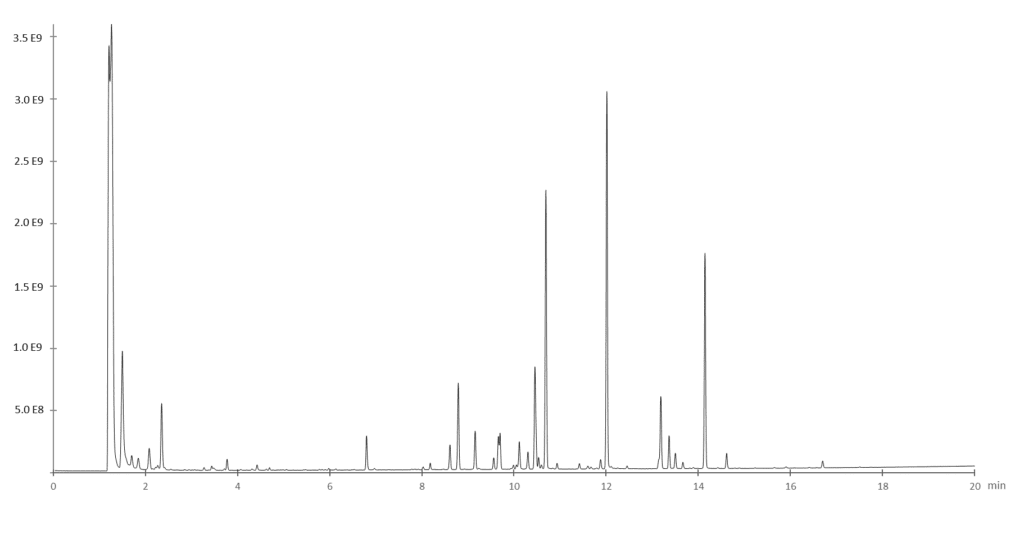

In niche applications that require custom formulations, air samples are taken from the plant and studied using GC-MS to determine precise molecular makeup. The GC-MS produces a chromatogram with peaks representing the quantity of each detected substance, and scientists then use this information to create blends of plant oils that neutralize each substance of concern.

Success across industries

Odor neutralizers have proven successful in many industrial environments, including pulp and paper mills, asphalt plants, wastewater treatment plants, chemical plants, and food processing facilities. One asphalt plant required an odor control solution that would remain effective through seasonal mix variations.

The plant shipped samples of three different asphalt mixes to Ecosorb’s lab to assess the levels of hydrogen sulfide, mercaptans and general hydrocarbons in each.

After analysis and per Ecosorb’s recommendation, the plant began using Ecosorb’s 1300A formulation in all its mixes, reducing airborne sulfurous release by over 90%.

Plant-based odor neutralizers are a safe, effective, cost-efficient, and sustainable means of odor control. By partnering with expert suppliers and employing targeted neutralization strategies, process manufacturers can create pleasant and healthy environments for employees and surrounding communities.