Effective Odor Control with Plant-Based Neutralizers

By Dr. Laura Haupert, Ecosorb

While often overshadowed by primary process concerns in many facilities, offensive odors cannot be ignored. The following is a summary of my article in the March 2023 issue of Control Engineering, titled “Odor measurement, control at industrial plants,” which discusses how processors can apply plant-based products to chemically neutralize the odor-causing constituents in industrial applications.

The problems with conventional methods

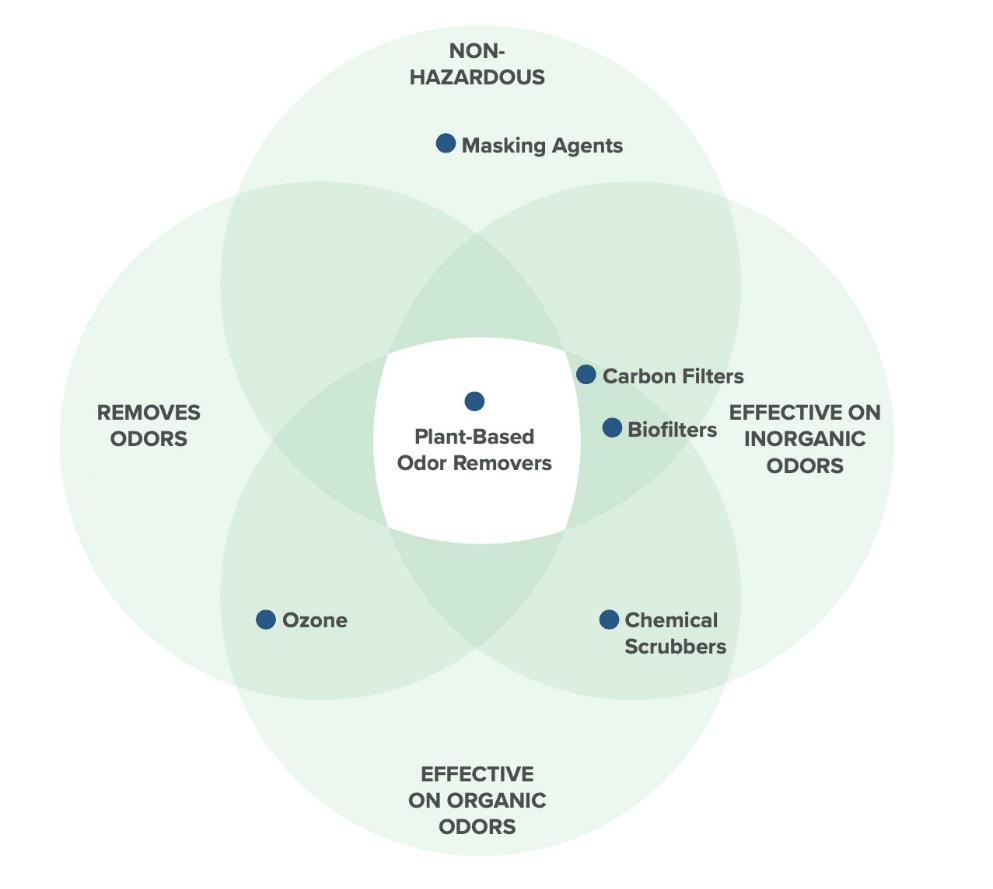

Malodors affect most process industries, and they can be offensive, or even harmful, to plant personnel and the nearby public. Conventional odor control solutions each have shortcomings—some are hazardous or ineffective against certain types of odors, and many are expensive and unwieldy to deploy.

In contrast, modern plant-based odor removers require relatively little equipment to deploy, and they safely span all odor removal applications by using research-based formulations, each specific to the odor being targeted for removal.

Meticulously formulated plant-based solutions

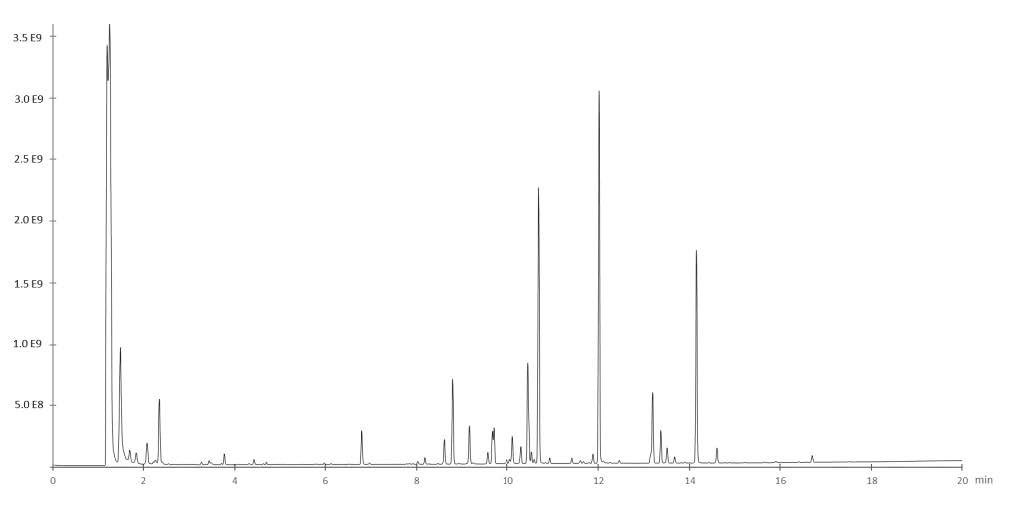

Plant-based neutralizers react with odorants at the molecular level. To determine the offending constituents, analysts collect gaseous samples from process facilities, and then use gas chromatography mass spectrometry (GC-MS) to identify precise composition.

After analysis, scientists formulate a blend of plant oils, biobased surfactants, and water that neutralize the odors on contact. Each of the process industries we serve have one or more Ecosorb formulations created to mitigate odors specific to an application.

Two dispersal approaches

Atomization systems combine concentrated odor eliminators with water and spray the mixture into the air. In these systems, high-pressure hydraulic systems propel the spray in open-air settings, while low-pressure fan systems are effective in confined spaces. Atomization systems are compact, flexible, customizable, and easy to transport and store.

Vaporization systems pump undiluted odor eliminators through perforated pipe distribution systems, creating a dry vapor to neutralize airborne odors. These flexible systems produce smaller droplets with higher absorption for increased odor control, and they require no additional water.

Results from the pet food and asphalt industries

With neighbors just a few hundred yards away, a large pet food manufacturer needed to neutralize odors from its wastewater collection area. To address this, engineers installed a vapor phase unit to deliver Ecosorb 806, a plant-based neutralizer specifically designed to react with the chemical composition of wastewater. After dialing in ideal flow rate and concentration settings, complaints from neighbors dropped sharply.

In another application, an asphalt manufacturer proactively sought to mitigate odors in the air surrounding its facility, prompted by nearby housing development construction. Chemical masking products failed to hide the smell, so the manufacturer approached Ecosorb and sent a product sample for analysis. Ecosorb 1200A—designed to reduce hydrogen sulfide, mercaptans, styrene, and general hydrocarbons in asphalt—proved effective, and the plant now adds about one gallon to each of its 6,000-gallon hot mix tankers.

Plant-based odor removers are safe, environmentally-friendly, and cost-efficient for neutralizing unwanted odors across multiple industries. They empower businesses to maintain rapport with neighbors and focus on operational optimization, instead of handling odor complaints.